Pre-Start Checks Made Easy

What is a Pre-Start Check?

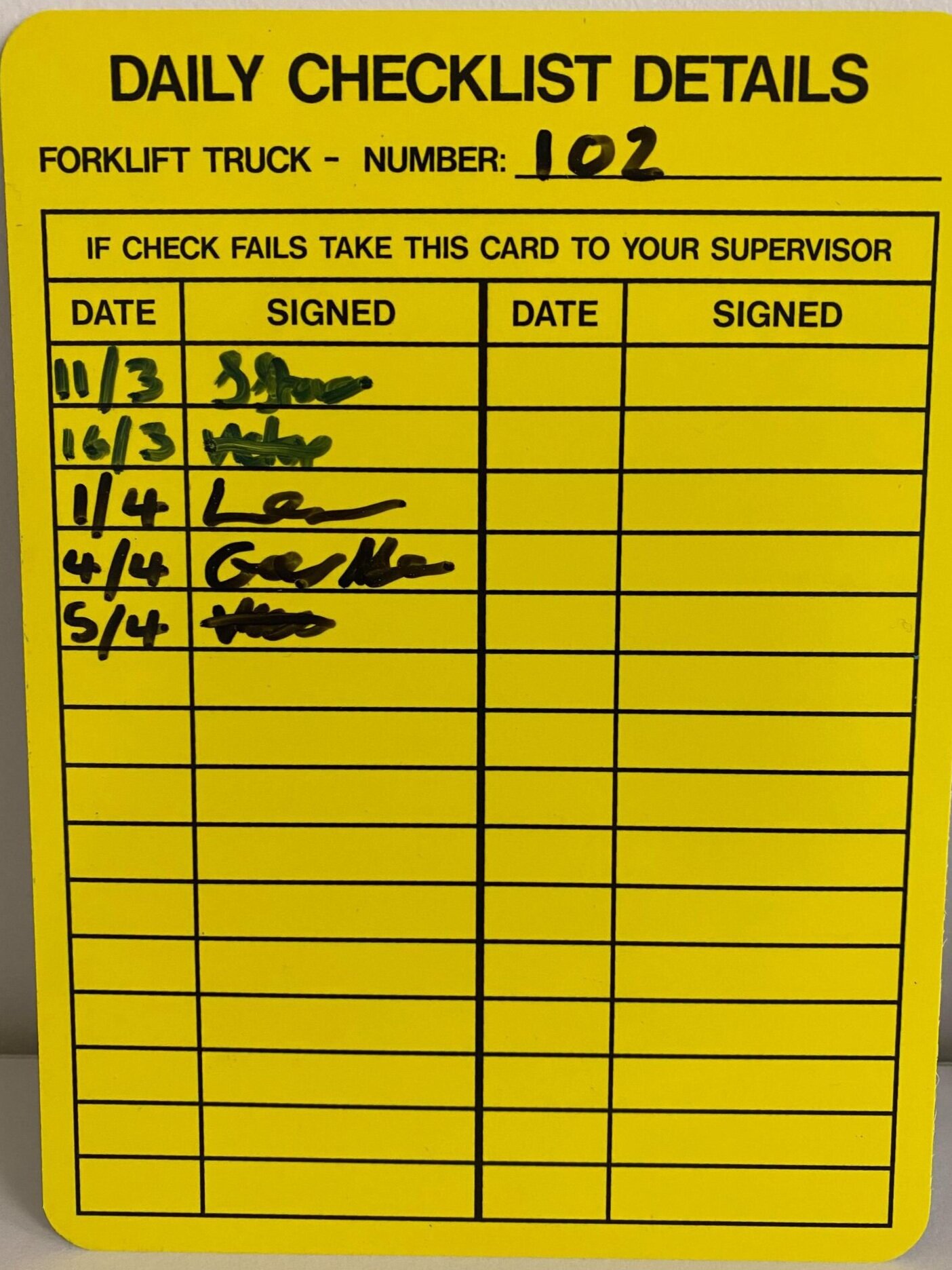

Pre-start checks are safety checks conducted on equipment before using the item. Commonly these are required for plant, equipment and machinery prior to being started or used each day.

Pre-start checks are routine inspections conducted by the equipment operator, usually with the aid of an inspection checklist. Where the checks are critical for safety, they are usually documented.

Pre-start checks identify safety deficiencies, maintenance problems or damage before the equipment is used: Reducing the risk of accidents or failures during use.

Why Conduct Pre-Start Checks?

Checking for damage or faults before starting equipment is important for safety.

Pre-start checks on mobile plant and production equipment can assist companies to identity and repair minor problems before they cause more serious problems or accident e.g. brakes, lights and steering operate correctly, and checking oil or water levels to ensure the plant operates correctly.

What Should be Included?

A checklist helps the operator conduct the pre-start check in a standardised way.

The contents of the pre-start checklist differs for each type of equipment. The equipment supplier usually provides detail of what should be included in the daily pre-start checks in the Operation Manual.

Pre-start checks should also confirm that the operator has the required licence or training to use the equipment.

Some common things to check:

Production machinery- Emergency stop buttons are accessible and working, all machine guards are in place.

Portable electrical equipment- electrical cord is not causing trip hazard or damaged, and inspection tag is within date, no physical damage to equipment, guards secured in place, any attachments are compatible and correctly attached.

Mobile plant- brakes, warning lights etc.

Example of a pre-start check

Using Digital Systems for Efficiency and Reliability

There are now software and Apps available to improve efficiency and record keeping of pre-start inspections.

With digital systems, pre-start checks can be recorded and help monitor compliance.

Some systems can prevent start of equipment if the pre-start inspection is not conducted, if critical items on the pre-start check are failed or if the operator does not have the required competency to operate. This helps to protect the operator and provides due diligence for the business.