What Is A Risk Assessment?

Many people complete what they think is a Risk Assessment, however, what they're really doing is only a ‘hazard hunt’.

One of our client’s workers lost their finger in a machine…

During our investigation, they told us they’d done a risk assessment but couldn’t work out why the accident had happened.

Our client thought they’d done everything right.

They’d walked around the machine. They’d documented all the issues they could spot.

They even installed some guards on some of the higher-risk issues. By the time they had finished, they’d found and dealt with many issues.

Whilst the machine was safer; the worker still lost their finger.

They never picked up the risk that caused that incident.

Then We Did Our Risk Assessment…

As part of our investigation, Safety Action performed a risk assessment on the same machine.

Our team very quickly found the cause of the accident.

In fact, we also found numerous other risks our client’s risk assessment had missed.

How could this accident happen when our client had made a genuine effort and performed their risk assessment on that very machine?

It turns out, although our client thought they did a risk assessment, what they’d actually done is a Hazard Hunt.

What was it that made our risk assessment and not a hazard hunt?

We asked the most important question…

The Most Important Question To Ask During A Risk Assessment

“Is this risk acceptable (in these circumstances)?”

There are only two answers to this question: “Yes” or “No”.

If you don’t include this question, and honestly answer it, it leads to the most common risk assessment mistakes.

What’s the mistake?

Your assessment doesn’t give management an answer!

Most risk assessments correctly document the known hazards, existing controls and assessed level of risk, usually using a tool called a ‘risk matrix’, yet still make this mistake.

If the outcome of your risk assessment isn’t a decision on acceptable or unacceptable risks, you’ve just “ticked a box” and filed a document.

Operational managers and supervisors need to know, before an accident if the activity or circumstance is safe and compliant, not simply that it is either a low, medium or high risk.

So…What Exactly Is A Risk Assessment?

A Risk Assessment is a process to help you identify and control risks.

A handy tool that can help guide the process is a risk assessment template which collates your findings and outcomes.

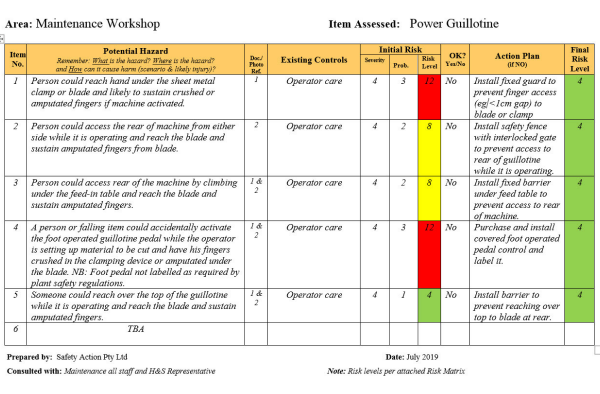

Below is an example of a completed risk assessment using our Universal Risk Assessment Form…

Contact us and we’ll send you the above example and a free copy of the Universal Risk Assessment Form. It's the same one that all of our safety consultants use.

You’ll be able to use the Universal Risk Assessment Form for pretty much any risk assessment you’ll need to do, including such things as:

Slippery floors.

Work at heights.

Machine guarding.

Adequacy of procedures.

Chemical storage.

Traffic management.

Not sure if you’re performing Risk Assessments correctly?

Become a Safety Helpline member and get a direct line to our highly trained safety consultants. With our help, you’ll be completing risk assessments that actually keep you and your workers safe - not just ‘ticking a box’.

You’ve Identified A Risk. How Do You Tell If The Risk Unacceptable?

It’s easy right?

High Risk = Don’t Do it

Low Risk = OK

This is a common way of thinking. It’s not hard to see why this is the starting point for most people.

At first glance, it seems intuitive & logical. But… does this match reality?

Let’s look at high risk activities…

We do high risk activities all the time.

Humans sent man to the moon.

Ride a motorbike and you’re 17 times more likely to be killed in an accident … But people still do it and it is legal.

Look at low risk activities

Imagine there's a hole in the carpet at your workplace.

It’s small, about as the size of a wallet.

A pretty low risk.

What if the hole is right at the front door of your offices or in your reception area?

Suddenly that low risk is not so acceptable.

It’s unlikely anyone will die or get seriously injured, however due to the high likelihood the tripping hazard could cause a person to fall and sustain a strain injury it becomes an unacceptable risk.

Here’s another example.

Consider a stop button on a machine in a factory? It’s black not red.

Everyone who uses it knows what it is. They’re told that during the induction and it’s clearly labelled as a stop button.

However…

Australian law says that stop buttons must be coloured red.

It might be trivial. It might be a low risk. But because of legal requirements, it’s an unacceptable risk.

There’s no formula

These examples highlight the importance of asking ‘Is This Risk Acceptable’ for every hazard you identify.

There’ll sometimes be high-risk issues you accept (and control) and low-risk ones you fix immediately.

There are multiple factors to consider. It’s not always black and white.

What Now?

Apply the principles mentioned above.

You’re on your way to conducting an effective risk assessment. Ones that keep you and your workers safe, not just tick a box.

What does that mean for you and your business?

Your team will not be surprised or injured by hazards or risks because you’ve already identified the risks.

You’ve found them. You’ve put action and precautions in place to minimise or mitigate them.

That’s what a risk assessment is.

If you’re not sure if you’re performing Risk Assessments correctly, consider becoming a Safety Helpline member and get a direct line to our highly trained safety consultants. With our help, you’ll be completing risk assessments that actually keep you and your workers safe - not just ‘ticking a box’. Click here to find out more about the Safety Helpline.